-

October 28, 2024

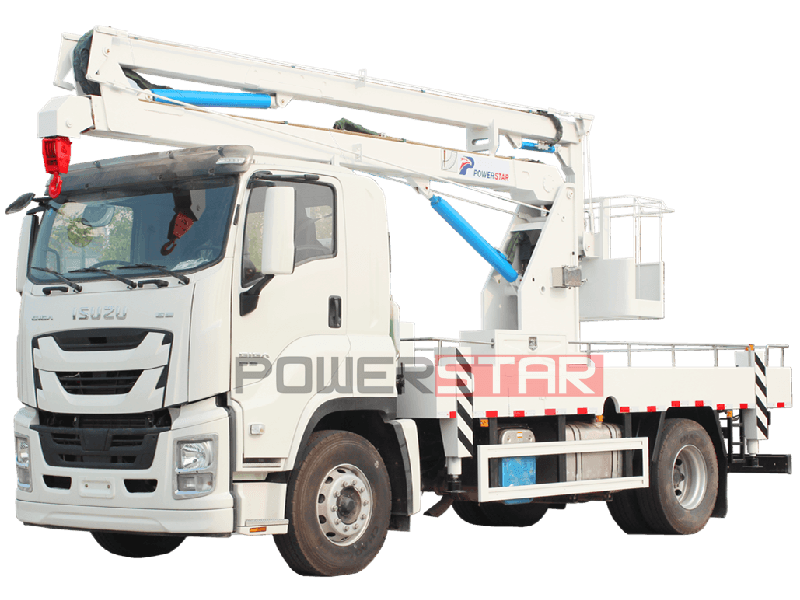

Isuzu folding arm aerial work platform truck is a kind of equipment specially designed for high altitude aerial work, which combines the original ISUZU truck chassis technology of Isuzu automobile and the advantages of folding arm aerial work platform, and widely used in Africa market, including in Djibouti, Ethiopia, Congo DR, Mauritania, etc. The Isuzu folding arm aerial platform truck, also called Isuzu manlifter truck, Isuzu high altitude platform truck, Isuzu truck mounted man lift, Isuzu truck work platform, Isuzu articulating platform truck. Isuzu aerial platform is a special vehicle that adopts Isuzu light duty NKR NPR truck chassis and carries articulating aerial work platform. Mounted with compact structure, easy to transport and quick to set up. The folding arm design enables the work platform to operate flexibly above various obstacles. Equipped with advanced hydraulic transmission system to achieve rapid lifting and precise positioning. Below showing details of the ISUZU 19m folding arm aerial platform trucks export Djbouti:

Isuzu folding arm aerial work truck is an efficient, safe and reliable high-altitude operation equipment with broad application prospects and market value. Below information detailed introduced the main configuration and functions of the original Japanese Isuzu technology truck mounted work platform, also guidance you how to use the Isuzu manlifter truck properly:

Chassis configuration: Isuzu manlifter usually use high-performance Isuzu NPR chassis, equipped with high-horsepower engines 4KH1CN model and engine power can be 120HP, 132HP, 140HP, etc. Emission can be EURO 6 standard with 2999cc. High-quality ISUZU brand transmissions MSB 5 shift or MLD 6 shift to ensure the stability and driving performance of the vehicle under various road conditions.Folding arm structure: The Isuzu NPR truck mounted folding arm aerial platform is made of high-strength steel plate and has a 360-degree full rotation function, which can achieve flexible operation. The arm is equipped with an auxiliary hook for convenient lifting operations.Working platform: The articulating working platform has a built-in combined leveling mechanism to ensure that the working bucket is always level. The rear-mounted design of the working bucket facilitates personnel entry and exit, while lowering the center of gravity of the vehicle and improving driving performance.Operating mechanism: The aerial platform operating mechanisms can be optionally equipped with an electronic control operating system, which is simple and convenient to operate. At the same time, the Isuzu truck mounted man lift is also equipped with safety devices such as manual emergency descent valves to ensure the safety of operators.

Isuzu truck mounted aerial platform are widely used in aerial operations in various systems such as municipal administration, electricity, street lights, advertising, communications, gardening, transportation, industry and mining, and docks.

1. Efficient and convenient: using advanced hydraulic transmission system, fast lifting speed, simple operation, can greatly improve the efficiency of high-altitude operations.2. Safe and reliable: Isuzu truck mounted articulating aerial platform equipped with a variety of safety devices, such as fall arresters, overload protection devices, etc., to ensure the safety of operators. At the same time, after strict quality testing and certification, the stability and reliability of the product are ensured.3. Wide range of applications: Isuzu truck manlifter can meet the needs of a variety of high-altitude operation scenarios, replace traditional manual climbing or use of scaffolding and other methods for high-altitude operations, and reduce the labor intensity and risks of operators.

-

October 17, 2024

ISUZU 4000L tanker truck refers to an Isuzu sprinkler truck, Isuzu water tanker, which based on original Japanese ISUZU truck chassis, equipped with an ISUZU brand diesel engine 4KB1-TCG60 model, maximum 132HP and emission 2499cc, the oval shape water tanker with customized capacity of loading 4,000 liters of water. ISUZU 4000L sprinkler truck is a powerful and well-equipped sprinkler equipment that plays an important role in maintaining the urban environment, protecting the road surface, and reducing air pollution. And this small type water bowser tanker truck is very popular in Mongolia market.

An Isuzu tanker truck is a motor vehicle designed to carry water or other liquid on roads. The largest such vehicles are similar to railroad tank cars, which are also designed to carry liquid loads. Many variants exist due to the wide variety of liquids that can be transported. Isuzu Tank trucks that uses an ISUZU brand engine, which is known for its reliability and efficiency. Also the designed capacity can load about 4,000 liters of water to meet the needs of sprinkling a large area. The tank body is generally made of high-strength materials, such as carbon steel plates, to ensure its durability and pressure-bearing capacity. The inside of the tank body may be treated with anti-corrosion to extend its service life. Anyway, to meet some customer special requirement, we POWERSTAR produced Isuzu water tanker can be mounted with PP material tanker, which is not rust, also can be used as food grade stainless steel 304-2B material for drinking water delivery.

ISUZU 4000L water bowser trucks are widely used in watering operations in urban roads, squares, parks, gardens and green spaces. They can not only reduce road temperature, prevent dust and reduce air pollution, but also be used for tasks such as green irrigation and emergency fire fighting.Spraying device: Isuzu sprinkler tanker truck is equipped with a variety of spraying devices, such as front flushing, rear sprinkling, side spraying, etc., to meet the needs of sprinkling in different occasions. Some models are also equipped with greening sprinkler cannons, which can realize the full rotation of water columns and the adjustment of various shapes (such as columnar, heavy rain, moderate rain, light rain, drizzle, mist, etc.), which is convenient for watering roadside flowers and trees or washing dust on trees.Water pump: Equipped with a self-priming sprinkler pump, it can quickly extract the water in the tank and spray it out. Some models are also equipped with debris filters to prevent the water pump from clogging.Power take-off: In order to drive equipment such as sprinkler pumps, sprinkler trucks are usually equipped with power take-offs.Music speakers: Some models are also equipped with music speakers, which can play music during watering operations to remind pedestrians and vehicles to avoid.Cab control: There are some high standard design for water trucks, which use air controller to be connect with all valves, which control switch in the cab to facilitate the driver to operate various spraying devices of the sprinkler truck.

1. When using an Isuzu water bowser tanker sprinkler truck, you should pay attention to safe driving and abide by traffic rules.2. Regularly check whether the various equipment of the tanker truck is working properly to ensure its stable and reliable performance.3. During the watering operation, the spraying device and the shape of the water column should be adjusted according to actual needs to achieve the best effect.

-

October 16, 2024

Isuzu NPR truck mounted crane transporter, referred to an ISUZU truck mounted crane or ISUZU crane truck, which is a special vehicle that integrates lifting and transportation functions. Isuzu crane lorry usually uses hydraulic lifting and telescopic systems to achieve the lifting, rotation, and lifting of goods. These functions are completed by the crane (crane) installed on the chassis of the truck. Djibouti customer purchase ISUZU NPR truck mounted crane and mainly used for construction project in Djibouti Seaport, below showing how to use the Isuzu crane mounted dropside cargo body.

The following is a detailed analysis of Isuzu NPR cargo crane truck:

Chassis: Isuzu NPR truck chassis can be standard as 4x2 or customized offroad 4x4 model, which provides solid carrying capacity and good driving performance. The medium type series is the leader among Isuzu trucks and has won the trust of users around the world with its excellent performance and reliability.Cargo compartment: As needed, the Isuzu crane truck lorry equipped with full dropside cargo body for loading non-lifting items or as an auxiliary platform during lifting operations.Power take-off: The power take-off is a key component connecting the engine and the crane power system, responsible for providing power to the crane.Crane (crane): The POWERSTAR boom crane is the core component for realizing lifting operations, including telescopic arms, variable-length cylinders, winches, hooks and other components, which can complete the lifting, rotation, and lifting of goods.

Isuzu NPR truck crane transporter is a special vehicle with powerful functions and excellent performance, which is widely used in various lifting and transportation operations. POWERSTAR produced and export Isuzu crane mounted cargo trucks with advanced features, mainly with below "VESA" feature:

1. Versatility: Isuzu NPR truck crane can be used for both cargo transportation and lifting operations, and is suitable for a variety of work scenarios.2. Efficiency: Through the hydraulic system and precise mechanical structure design, fast and accurate lifting operations are achieved, improving work efficiency.3. Stability: The Isuzu crane truck chassis and crane are reasonably designed to remain stable during the lifting process and ensure safe operation.4. Adaptability: According to different needs, chassis and crane configurations of different tonnages can be selected to meet various lifting and transportation needs.

Isuzu NPR truck cranes are widely used in stations, warehouses, docks, construction sites, field rescue and other places. They are indispensable and important equipment in urban construction, logistics transportation, emergency rescue and other fields. That is the reason ISUZU NPR crane trucks are popular and widely used in Asia, Africa, South America and Latin America, etc.When using Isuzu NPR truck cranes for lifting operations, you must strictly abide by the safety operating procedures to ensure the safety of personnel and equipment.Maintain the vehicle regularly and check whether the hydraulic system, mechanical parts, electrical system, etc. are working properly to extend the service life of the vehicle and improve work efficiency.When selecting and using a crane, it should be reasonably configured and selected according to specific needs and the operating environment to ensure the operating effect and safety.

-

October 14, 2024

Isuzu 20m straight arm aerial work platform vehicle is a special vehicle designed for aerial work. Isuzu 20m manlifter truck is widely used in many fields such as construction, aviation, and electricity. In the field of construction, Isuzu straight aerial platform trucks can be used to install and repair lamps, air conditioners and other equipment in high-rise buildings; in scenes such as aviation ports or power line maintenance, Isuzu telescopic high altitude working platforms can also be competent for many difficult-to-reach high-altitude tasks. In addition, Isuzu manlifter trucks are also suitable for climbing and maintenance projects in many industries such as municipal construction and landscaping. Below pictures showing how to use the Isuzu manlifter trucks from us POWERSTAR:

As a powerful, stable, and flexible aerial work equipment, Isuzu 20m Aerial Platform Truck can meet a variety of aerial work needs and is one of the indispensable equipment in modern urban construction. Main technical parameters: including chassis model, length, width, height, wheelbase, engine emissions, etc. For example, a certain model may use the Original Japanese ISUZU truck chassis, with dimensions of 6500×2200×3250mm and a wheelbase of 3360mm, which meets the EURO 6 emission standards. Working height: The maximum working height can reach 20 meters, which can meet various high-altitude working needs. Working range: At the maximum working height, the working range may reach about 8.9 meters, ensuring that a wider area can be covered during high-altitude working.

As the working famous aerial platform truck supplier, we POWERSTAR can customized to produce different type manlifters, all with below advanced features:

Boom form: It adopts a four-section telescopic boom design, and the telescopic cylinder is built-in with a wire rope transmission, which is compact and stable. The boom material is mostly high-strength steel plate, such as HQ60/5mm, and the boom cross-section is usually diamond-shaped to enhance the force bearing capacity and structural strength.

Outrigger type: front and rear H-shaped outriggers, good stability, the outrigger materials are mostly low-alloy steel such as Q345B/5mm, the outrigger span is large, and it can adapt to various working conditions and ground conditions.

Rotation system: It has a two-way 360° continuous rotation function, adopts an advanced planetary gear reduction mechanism, has self-lubrication and self-locking functions, and improves working efficiency and safety.

Isuzu 20m straight high altitude aerial platform truck is a powerful, stable and flexible aerial work equipment that can meet a variety of aerial work needs and is one of the indispensable equipment in modern urban construction.Lifting platform: Provide a stable lifting platform to ensure that workers can work safely and efficiently when working at high altitudes. The platform also equipped with a static hydraulic automatic leveling system to ensure stability during operation. Also can be equipped with insulated basket for electric workingOperating system: Supports manual and electric combined operation, electro-hydraulic proportional speed regulation, and flexible and convenient operation. The boom movement and hanging basket control may adopt a two-position operation design with a controller and display screen to improve operation accuracy and safety.Safety protection: Equipped with multiple safety protection functions, such as leg locking, automatic working range limitation, etc., to ensure the safety of personnel and equipment during operation.Remote control operation: The basket also adopt unlimited remote control operation to improve the convenience and flexibility of operation. Standard English language, also can be customzied as French, Russia, Arabic, Spanish, etc.

-

September 10, 2024

El camión de chorro combinado Isuzu es un vehículo especial para residuos diseñado para eliminar eficientemente obstrucciones en desagües y alcantarillas. Equipado con un sistema de chorro de alta presión, este camión de chorro combinado Isuzu puede entregar un potente chorro de agua para desalojar residuos y obstrucciones, asegurando un flujo óptimo en las tuberías.

El sistema de chorro del camión combinado Isuzu es capaz de producir presiones de hasta 4000 PSI, lo que le permite eliminar eficazmente las obstrucciones difíciles sin causar daños a las tuberías. Además del sistema de inyección, el camión de inyección combinado Isuzu también cuenta con un potente sistema de vacío que puede eliminar rápida y eficazmente los residuos y lodos de las tuberías, asegurando un proceso de limpieza exhaustivo.

Exportar un camión de propulsión combinado Isuzu a Djibouti requiere una planificación cuidadosa y el cumplimiento de las normas de importación/exportación. Estos son los pasos para exportar con éxito camiones de propulsión combinados Isuzu. Es importante investigar e identificar compradores o distribuidores potenciales en Djibouti que estén interesados en comprar un camión de propulsión combinado Isuzu. Esto se puede hacer a través de mercados en línea, ferias comerciales o comunicándose directamente con empresas locales.

Una vez que se ha identificado un comprador o distribuidor potencial, el siguiente paso es determinar la logística de exportación del camión jet combinado Isuzu a Djibouti. Esto incluye obtener las licencias y permisos de exportación necesarios, así como organizar el transporte y el envío.

Investigar las regulaciones de importación: el primer paso es investigar las regulaciones de importación de vehículos de Djibouti. Asegúrese de que el camión de propulsión combinado Isuzu cumpla con todos los requisitos necesarios, como estándares de emisiones, características de seguridad y documentación.2. Encuentre un exportador confiable: busque un exportador confiable que tenga experiencia en el envío de vehículos a Djibouti. Pueden ayudar con la logística del envío del camión jet combinado Isuzu, incluida la organización del transporte, el manejo del despacho de aduanas y garantizar que el vehículo llegue de manera segura.3. Obtenga la documentación necesaria: reúna toda la documentación requerida para exportar el camión jet combinado Isuzu, incluido el título del vehículo, la factura de venta, la declaración de exportación y cualquier otra documentación relevante. Asegúrese de que todos los documentos estén correctamente completados y certificados.4. Prepare el vehículo para el envío: antes de enviar el camión jet combinado Isuzu, es necesario prepararlo para el transporte. Esto incluye asegurarse de que esté limpio, vaciar el tanque de combustible, desconectar la batería y asegurar cualquier elemento suelto dentro del vehículo.5. Organizar el transporte: trabaje con el exportador para organizar el transporte del camión combinado Isuzu hasta el puerto de salida. Dependiendo de la ubicación del vehículo, esto puede implicar contratar una empresa de transporte o conducir el vehículo hasta el puerto usted mismo.6. Pasar por la aduana: una vez que el camión de jet combinado Isuzu llegue al puerto de salida, deberá pasar por el despacho de aduana. Proporcione toda la documentación necesaria a los funcionarios de aduanas y pague las tarifas requeridas para liberar el vehículo para su envío.7. Envíe el vehículo: El camión de propulsión combinado Isuzu se cargará en un buque portacontenedores o en un buque de carga y descarga para su envío a Djibouti. Trabajar en estrecha colaboración con el exportador para realizar un seguimiento del progreso del envío y garantizar que el vehículo llegue a su destino a tiempo.8. Reciba el vehículo en Djibouti: una vez que el camión jet combinado Isuzu llegue a Djibouti, deberá pasar por el despacho de aduana nuevamente. Proporcione toda la documentación necesaria a los funcionarios de aduanas y pague las tarifas requeridas para liberar el vehículo.9. Registre el vehículo: después del despacho de aduana, registre el camión de propulsión combinado Isuzu ante las autoridades locales de Djibouti. Esto puede implicar el pago de tarifas de registro y la obtención de placas para el vehículo.

Si sigue estos pasos y trabaja con un exportador confiable, podrá exportar con éxito un camión de propulsión combinado Isuzu a Djibouti y garantizar un proceso fluido y eficiente.

-

September 06, 2024

El camión aspirador Isuzu 100P es un vehículo potente y eficiente diseñado para la limpieza y mantenimiento de sistemas de alcantarillado y fosas sépticas. Operar este camión Isuzu Vacuum requiere atención cuidadosa a los detalles y una comprensión adecuada de sus funciones. Aquí hay una guía paso a paso sobre cómo operar el camión aspirador Isuzu 100PPaso 1: Arranque el motor- Inserte la llave en el encendido y gírela en el sentido de las agujas del reloj para arrancar el motor.- Deje que el motor se caliente durante unos minutos antes de operar el camión aspirador.Paso 2: active el sistema de vacío- Ubique el panel de control de la bomba de vacío en el tablero.- Encienda la bomba de vacío moviendo el interruptor a la posición "on".- Ajuste la presión de vacío según sea necesario usando la perilla de control en el panel.Paso 3: comience a aspirar los desechos- Coloque la manguera de vacío sobre el material de desecho que necesita ser succionado.- Utilice el control de la palanca de mando para maniobrar la manguera de vacío y controlar el proceso de succión.- Supervise el indicador de nivel del tanque de desechos para asegurarse de que no exceda la capacidad máxima.Paso 4: Vaciar el tanque de residuos- Una vez que el tanque de desechos esté lleno, estacione el camión aspirador en un área segura y nivelada.- Apague la bomba de vacío y active el sistema de drenaje del tanque.- Utilice la manguera provista para vaciar el tanque de desechos en un área de eliminación designada.

October 28, 2024

October 28, 2024